For decades scientists have been attempting to unleash the extensive stored energy locked in aluminum because it has one of the highest levels available in any metal or fuel. We can see the power of aluminum when its powder is ignited in fireworks.

The driving force in these endeavors was the need to find a reliable, lightweight power source for sophisticated, military and space applications. The weight and limited performance and shelf life of traditional batteries were just not acceptable. Most companies have used aluminum alloys in production, at a significant cost increase. In addition, expensive additives were added to the mix. Both these issues hampered the recycling of the by-products and created unwanted wastes. These factors, combined with the inability to create an affordable final product, substantially reduced the general commercial viability for all but specialized uses.

The challenge has been to make cost competitive, efficient products.

Altek Fuel Group, Inc., an alternative energy company, has overhauled all existing drawbacks and developed an affordable “breakthrough” Aluminum-Air alkaline power supply, which will fulfill tremendous demand for a long lasting autonomous power source.

Altek has undertaken a completely new approach to the use of aluminum as the source of energy for fuel cells including the use of industrial aluminum and a more optimized electrolyte mixture to dramatically release the inherent energy. Furthermore, the use of proprietary, but readily available chemicals simplifies the process, making it commercially viable.

Altek’s fundamentally new technology enables development and manufacturing of a commercial , autonomous electrical power source or universal battery charger, with much longer performance, at least 5 to 10 times the longevity of currently available batteries.

The major market divisions for Altek’s product line is portable, stationary and military applications.

Within the portable market, the key demand comes from the myriad of electronic products presently currently served by regular alkaline and Li-based batteries and each of them are “Power Hungry” which means a lack of power performance of existing batteries. Many portable products use batteries to supply their power. Although battery technology is constantly improving, it is unlikely that these improvements will meet all of the future requirements. This includes the telecommunications industry, computers, electronic games, gadgets, and a range of safety and business related equipment. It is by new efficient solution to providing longer power and a number of new and exciting products will developed.

The stationary/home market includes independent electrical sources for the home, business and institutional applications. Where no electrical grid exists, Altek fuel cells should be able to provide power to households or businesses with more reliability than a battery or generator. Even in countries with a grid system, it may be extremely expensive for a remote household to connect to it. In this case, there could simply be a much lower capital (and operating) cost than paying for the connection and electricity afterwards. It allows for an uninterruptible energy supply for backup purposes or for the ability to operate separately from the electrical grid. The systems can be located almost anywhere and can facilitate the development of operations in remote places anywhere in the world. The size of the installation can grow over time since the system is fully scalable.

The military industry applications allow for the development of the true 21st Century armed forces. Every aspect of the communications and operations for individual soldier will substantially improve by high performance Altek’s system. Any equipment needed in the field can have an enhanced capability. Furthermore, the necessity for establishing virtual cities in combat to handle a range of activities can be more efficiently with substantially more power and performance. All aspects of command and control, logistics, surveillance, etc. will affected. Using the new efficient Altek fuel cell systems will provide military planners and equipment designers with a much-needed new and improved power system.

By relentlessly developing and improving our technology, we will make a real difference.

GAS DIFFUSION ELECTRODES AND MEMBRANE ELECTRODE ASSEMBLIES FOR FUEL CELLS

Patent # US 8,64 7, 787

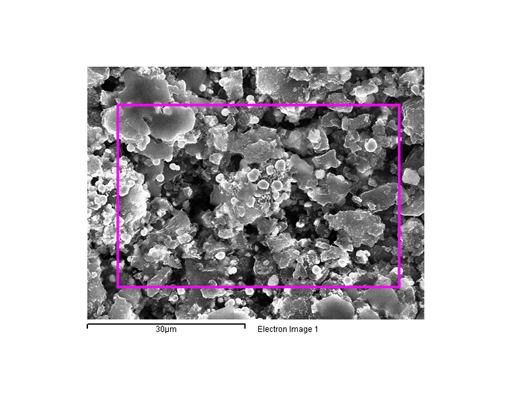

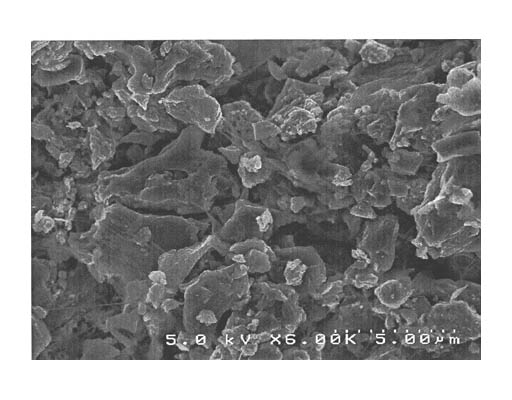

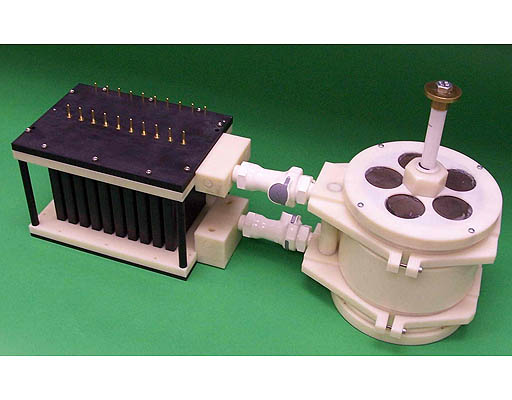

ALTEK has developed proprietary Gas Diffusion Electrodes (GDEs) suitable for alkaline aluminum-air fuel cells and for of Membrane Electrode Assembly production (MEA) in PEMFC.

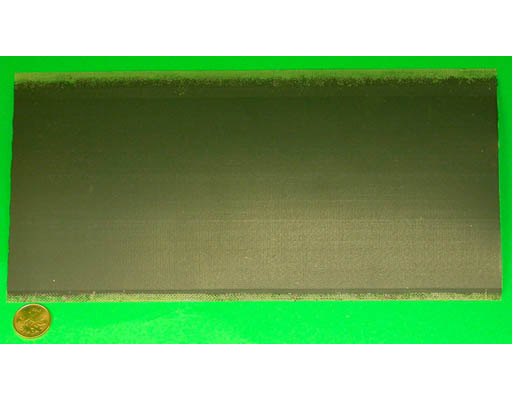

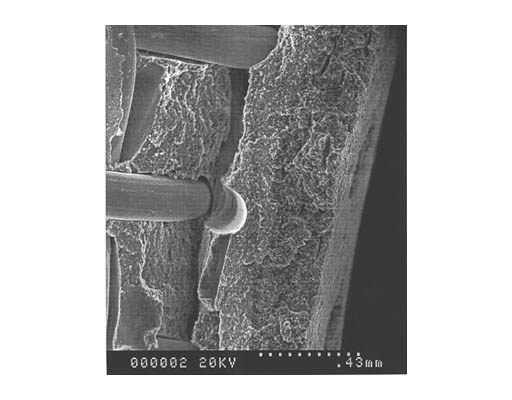

AGF’s Gas Diffusion Electrode based on a unique porous catalyzed structure fitted as a cathode in alkaline fuel cell, partly in metal-air fuel cell. The commercial manufacturing process fabrication is fully reproducible and based on extruded all in one design with minimal labor.

AFG’s GDEs for PEM/Alkaline fuel cells are suitable for portable/residential/transportation applications.

ALKALINE ALUMINUM-AIR FUEL CELL POWER SUPPLY

Patent No.: US 8,173,307 B2

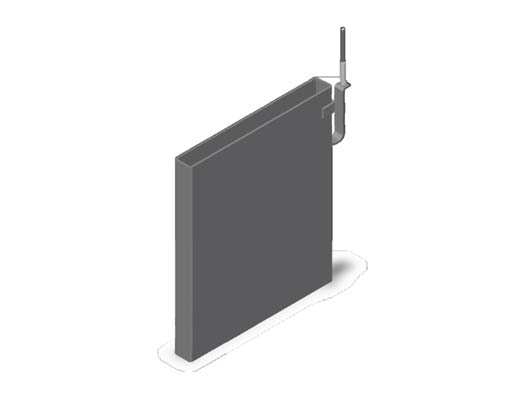

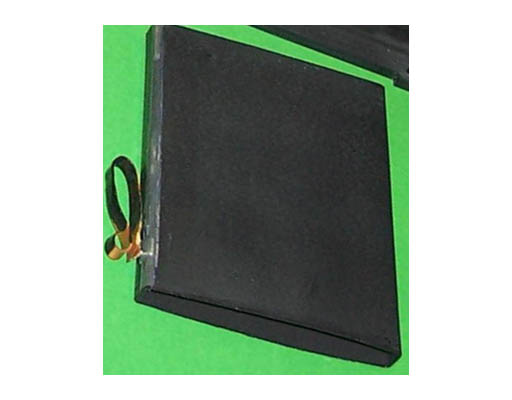

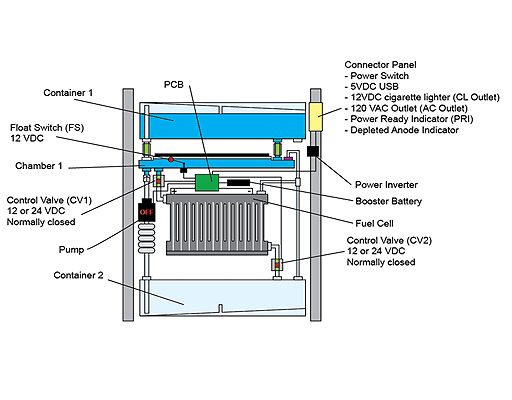

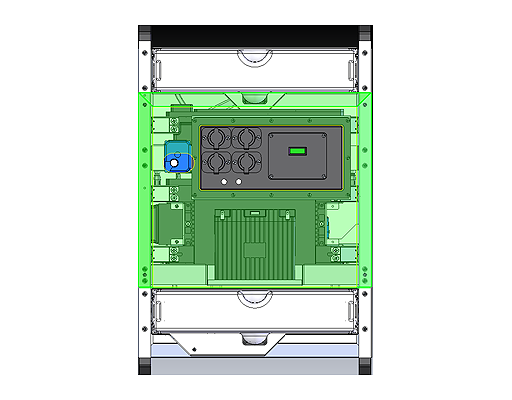

APS 100APS 100 has a specific energy of over 300 Watt-Hours /kg and offers an ideal design to integrating into numerous portable and stationary applications.

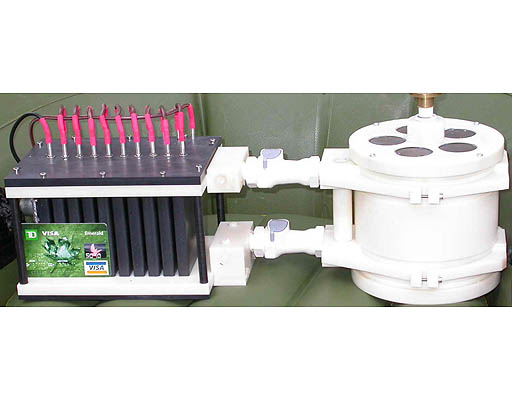

With a continuous power output over 100 watts, Altek’s APS 100 Fuel Cell Power Supply features efficiently designed all proprietary catalyzed gas diffusion electrodes, industrial anode alloys and composite electrolyte.

APS 100 also features the ability of mechanically recharge the electrical capacity without any power interruption by using Altek's Fuel Cartridges. This allows the APS 100 to be fully independent from the electrical grid and, therefore, ideally suitable for store energy in remote areas.

After 12 years in use APS100 for validation, demonstration and lab-testing purpose Altek’s team have reached over 3000 work hours on each of three units manufactured yearly in 2005.

Up to date each unit have storage time over 120000 hours.

After testing APS100, we have found decreased performance about ~50per cents from beginning, as an example the output net power shows 55-60 watts instead of 100 on freshly manufactured units, but the Voltage is still the same.

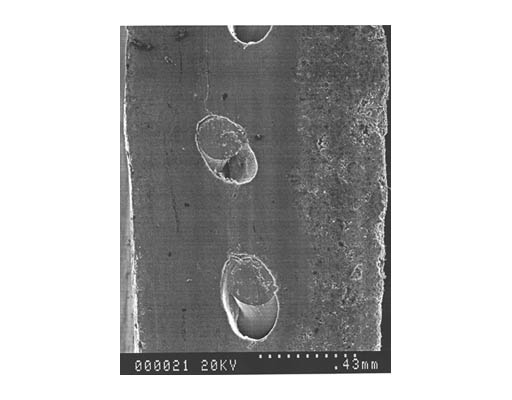

The main source of degradation is changed porous structure of gas diffusion cathodes issued by plugged hydrophilic tunnels fronting to electrolyte side. This is the main challenge and ALTEK’s team working on to extend lifetime.

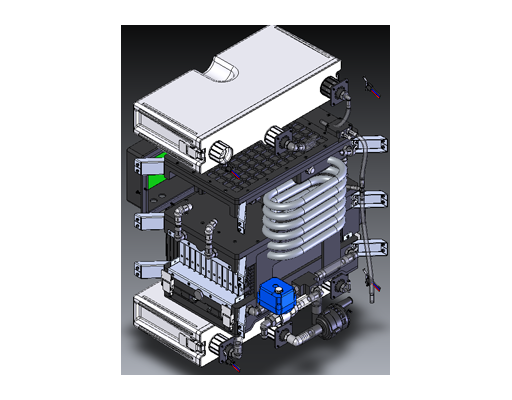

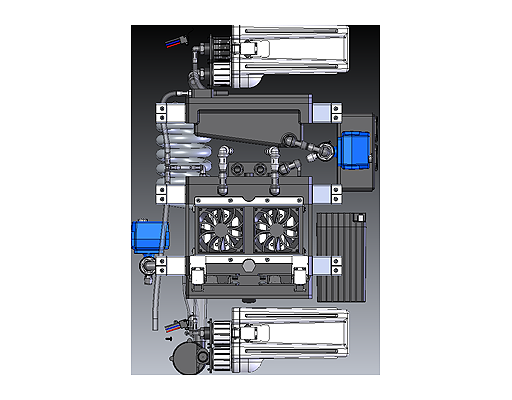

In continuation of R&D activity, we have started to design APS250 as a new approach of APS technology based on ALTEK’s proprietary hybrid fuel cell platform.

The APS250 unit design have several new improvements:

- ➔ Fuel cell pack design with new approach of anode cartridge concept and cathode sealing;

- ➔ Two electrolyte tanks with easy replace electrolyte cartridge;

- ➔ Hydrogen utilization subsystem combined with system initialization;

- ➔ Electrolyte system management combined with heat management;

- ➔ Control system with auxiliary Li-Ion battery to improve voltage/power management, energy utilization/distribution and quick start time;

- ➔ Designed power panel to meet more suitable customer interface;

- ➔ All parts of APS250 unit are designed to meet mass production requirements

At the same time to design APS250 hybrid fuel cell system ALTEK‘s team find the new concept to develop a completely new off-grid autonomous power supply based on integrated hybrid fuel cell, photo-voltaic, batteries and wind generator subsystems. This combination is completely new approach in autonomous power generators with significant synergy effect to increase efficiency of entire power system.

HYDROGEN PRODUCTION

Patent No.: US 8,858,910 B2

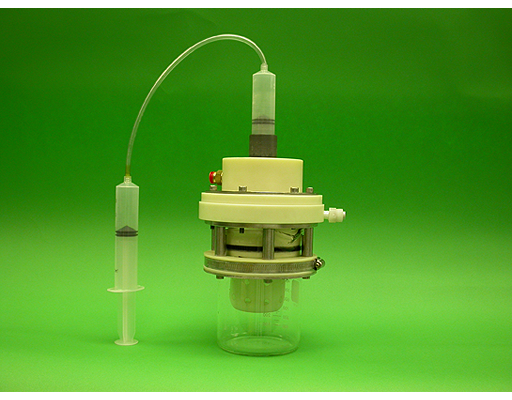

ALTEK has developed unique methods for hydrogen production by aluminum assisted water split technology.

These proprietary hydrogen on-demand production technologies are inexpensive and environmentally safe. Altek presents three Hydrogen Fuel Sources for the fuel cell. These are low pressure (less than 10psi), hydrogen on-demand sources These hydrogen sources are based on the release of hydrogen from chemically bonded compounds.

Hydrogen released from chemically bonded compounds through chemical reactions yield 3.7-11.1 weight percent:

- - hydrogen from water by aluminum assisted water split:

3.7 Wt.% without secondary use of water;

7 Wt.% with secondary use of generated water from fuel cell power plant; - - hydrogen from water by aluminum hydrolysis:

5.55 Wt.% - without secondary use of water;

11.1 Wt.% with secondary use of generated water from fuel cell power plant; - - 7-10 Wt.% - hydrogen from sodium borohydride

These hydrogen sources are self-contained units to create a virtually unlimited environmentally safe source of hydrogen.